Many industries are looking to outsource CNC machining services to save time and money. This kind of production process is ideal for small and medium-sized businesses, as these businesses have the flexibility to customize parts to fit their needs. In addition, these types of manufacturing services can produce parts to any 2D drawing, ensuring the highest quality and on-time delivery. For more information on CNC machining, click the link below. Further reading: What is CNC machining?

CNC machining services

CNC machining services are widely used in the aerospace, energy, and oil and gas industries. Products produced by the aerospace industry include compressor cases, separation discs, electronic enclosures, instrument panels, and gear housings. In addition, the energy industry uses CNC machining for solar cells, light assemblies, and hubs. Oil and gas products include actuating and sealing systems, wrist pin bushings, and spherical bearings.

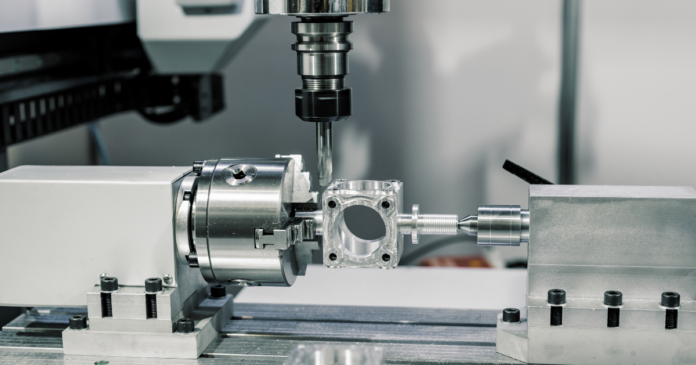

CNC machining is a subtractive manufacturing process

It uses computer-controlled machine tools to remove layers of material from a workpiece. It is the preferred method of rapid prototyping for custom-made parts made of metal or plastic. In addition, it can be used to produce tooling for pressure-die casting and plastic injection molding. Further, CNC machining services are also excellent for prototyping. The versatility of CNC machining makes it a valuable option for many companies.

CNC machining services can also be useful for testing plastic parts. A prototype part made by a CNC milled machine will ensure that the design is sound before the final mold is produced. Additionally, a CNC molded prototype can be manufactured without having to purchase any tools or prototypes. With this technology, it is possible to test injection-molded parts without the need to purchase expensive tools. Moreover, CNC machining services can also save a lot of time because the process doesn’t require any tooling.

CNC machining services are a great way to reduce the cost of custom parts

With the help of CNC machines, CNC machining can be done on a variety of materials and with extreme precision. If your parts are round or cylindrical, CNC machining is best suited. Similarly, if you have a part that requires high-precision and complex geometry, you can use CNC milling and CNC turning. In addition to the speed and accuracy, CNC machining can be used to produce one-off or small-production-volume products.

Nowadays, CNC machining services use CAM and CAD software to automate the process. For instance, you can send a CAD design to the company to create a CNC machined product. In the end, the CNC milling machine will follow the design and the software. This is why modern CNC machining services are so versatile. For larger parts, a machine can be programmed to make multiple layers of precision. A good CAM can create a product of any complexity.

CNC machining services are often used to manufacture prototype parts and volume parts

The specialized machines can create almost any shape or material. Besides, it is an efficient and cost-effective solution for short production runs. You can also benefit from a diverse range of metal finishing options. These machinists can also perform complex shapes. You can choose from aluminum, copper, and plastic for CNC machining. All CNC machines are scalable.

The advantages of CNC machining services over manual machining are many. First, they don’t need molds or expensive tooling. Instead, they can start a production process as soon as you have a digital file of your design. They can also handle complicated geometries and can offer a higher level of precision. A number of advantages of CNC machining services over manual machining include: ‘Machined parts’ are produced quickly. They do not require a mold to be made and can be accessed on the internet.

Conclusion

The advantages of CNC machining services are numerous. Various industries can benefit from this technology. Those in the automotive industry will have their parts manufactured in high-quality and functional prototypes. These prototypes are often tested in a laboratory before they are launched into production. These machines can be used for various types of vehicle parts and are especially suitable for metal and plastic parts under the hood. Alternatively, they can be used for showcases and lighting components.